Product Description

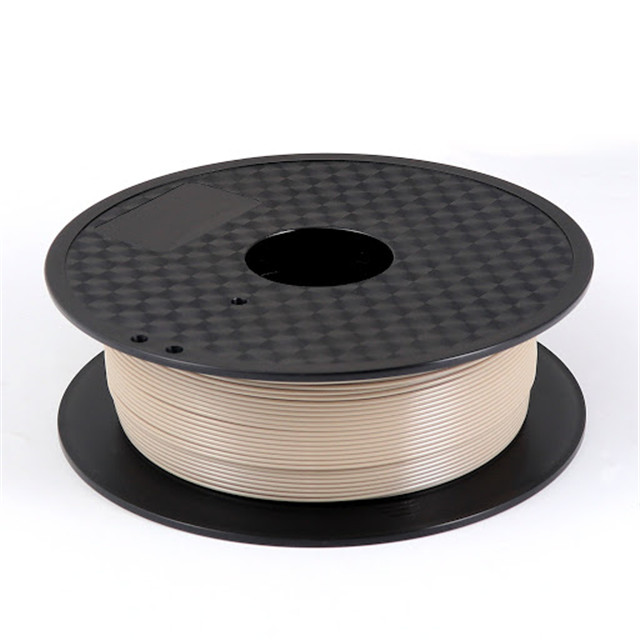

This mini 3D printing silk production line features automation, compact structure and small footprint.It uses PEEK or PEI materials to make a series of diameter 3D printing silk to meet the needs of 3D printing.The diameter of the printed wire is 1.75mm and 3mm.

Advantage

Low error printing wire control by small model precision screw;

Perfect tolerance:+/-0.03mm, even+/-0.01mm;

It can produce the different diameter of filament from 1.75mm-3.00mm;

Easy operation: Panel clean control system;

Produce different raw material:PEEK PEI PI PEKK ASA;

Low maintain. We did not receive any complaint once the machine is running;

We can provide installation services overseas.

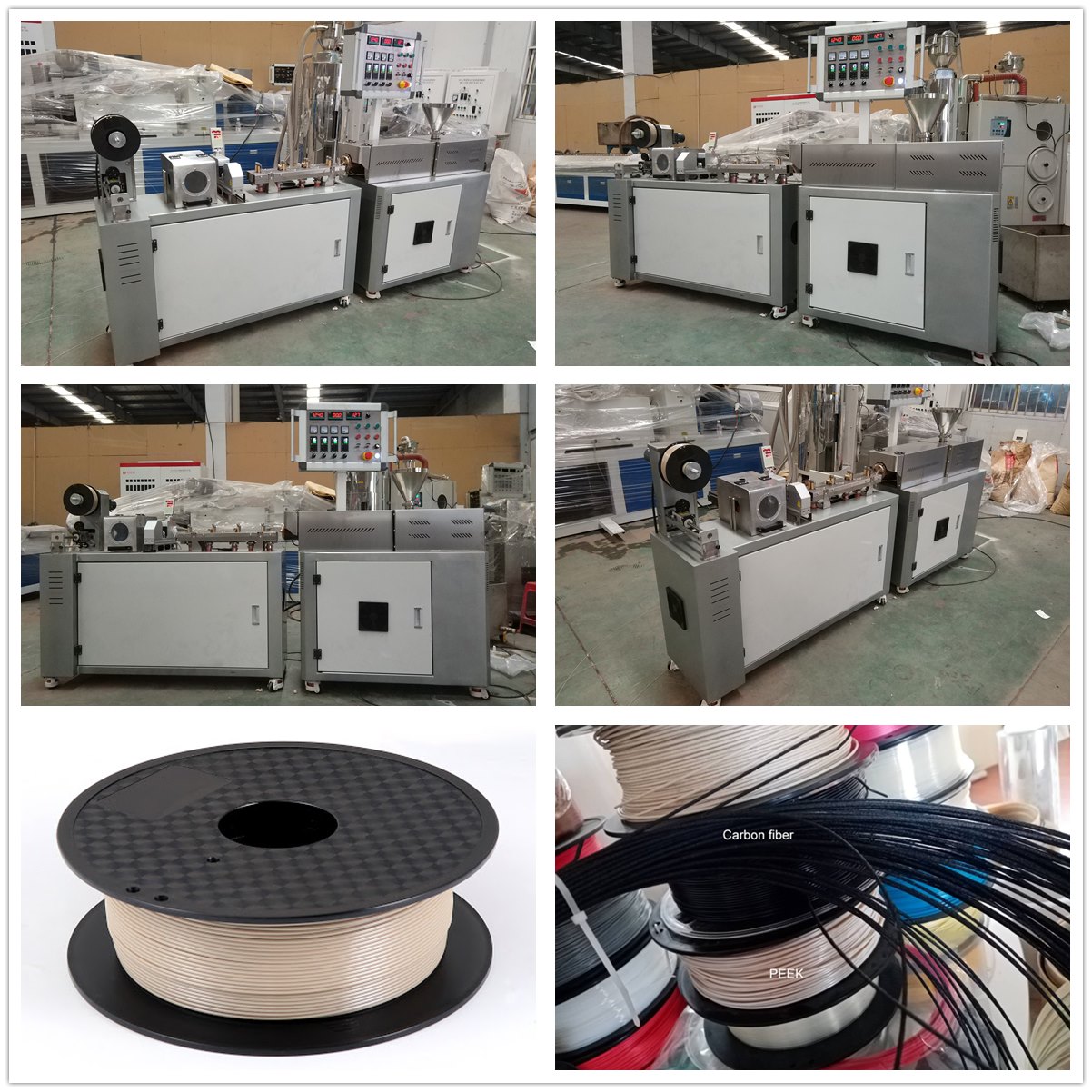

Production Flow

Hopper dryer——Single screw extruder——Die head——Cooling tank—— Laser measuring diameter machine—— Haul off machine——Storage wire stand——Winder machine

Production Line Parameter:

Type | FLDP-25 |

Applied materials | PEEK PEKK PEI Carbon Engineer plastic |

Screw diameter | 25mm |

L/D | 25 |

Screw Speed | 0-150rpm |

Linear velocity | 0-100m/min |

Filament diameter | 1.75mm、2.85mm、3.00mm |

Tolerance | ±0.02mm |

Heating/cooling way | Electrical heating/Fan cooling |

Operating Temp | Max 480℃ |

Control System | Siemens Control |

Capacity | 3kg/h |

Main motor Power | 7.5kw |

Control Type | Clean panel control |

Working Voltage | 3 Phase 380VAC±10%,1 Phase 220VAC±10%,50Hz |

L*W*H | 3500mm*550mm*1800mm |

Weight | 500kg |

Pictures